Product Information: SpiderMaker EX-300BL Engineering All-Rounder Resin (Black) for LCD 3D Printers, 1 kg

🔸 Brand: SpiderMaker

🔸 Material: Photopolymer Resin (Engineering-Grade with High Durability)

🔸 Color: Black ⚫⚙️

🔸 Net Weight: 1 kg

Why Choose SpiderMaker EX-300BL Engineering All-Rounder Resin (Black)?

SpiderMaker EX-300BL Engineering All-Rounder Resin (Black) is a high-performance photopolymer resin designed for engineering applications that demand durability, precision, and reliability. Its deep black color provides a sleek and professional finish, while its exceptional mechanical properties make it ideal for functional prototypes, end-use parts, and complex engineering projects. Whether you're printing gears, tools, or structural components, this resin delivers consistent performance with smooth surfaces and sharp details.

What Makes It Special?

🔹 Engineering-Grade Durability: Offers outstanding mechanical properties, including a tensile strength of 36.6 MPa, a tensile modulus of 1489 MPa, and a surface hardness of 82D, ensuring robust and long-lasting prints.

🔹 High Fracture Elongation (8.6%): Provides enhanced flexibility and impact resistance, making it suitable for parts subjected to stress or dynamic loads.

🔹 Moderate Viscosity (90-110 cps): Ensures smooth flow during printing, reducing the risk of clogging and improving layer adhesion for flawless results.

🔹 Versatile Applications: Ideal for both functional and engineering-grade prints, from mechanical components to intricate prototypes.

🔹 Professional Finish: The deep black color gives your prints a sleek and polished appearance, perfect for professional use.

Recommended Printing Settings:

🖨️ Printer Compatibility: LCD 3D printers

🌡️ Exposure Time (Base Layer): 10-15 seconds

⏱️ Exposure Time (Normal Layers): 2-4 seconds

💡 Wavelength: 405 nm

💧 Layer Height: 25-100 microns (recommended for optimal detail)

🛠️ Post-Curing: UV curing chamber or sunlight for 5-10 minutes (to achieve maximum hardness and stability)

Applications of SpiderMaker EX-300BL Engineering All-Rounder Resin (Black):

🔧 Functional Prototypes: Create durable and precise prototypes for product development, testing, and validation.

🛠️ Mechanical Components: Manufacture gears, brackets, clips, and other small parts that require strength and precision.

⚙️ End-Use Parts: Produce reliable components for robotics, drones, and other engineering applications.

💡 Tooling and Fixtures: Design custom jigs, fixtures, and assembly aids for industrial use.

🎨 Artistic Models: Craft detailed sculptures and artistic pieces with a professional black finish.

Why Customers Love It:

✅ Exceptional Mechanical Properties: Delivers high durability, impact resistance, and flexibility, essential for demanding engineering applications.

✅ Smooth Surface Finish: Produces clean, sharp edges and smooth surfaces with minimal post-processing.

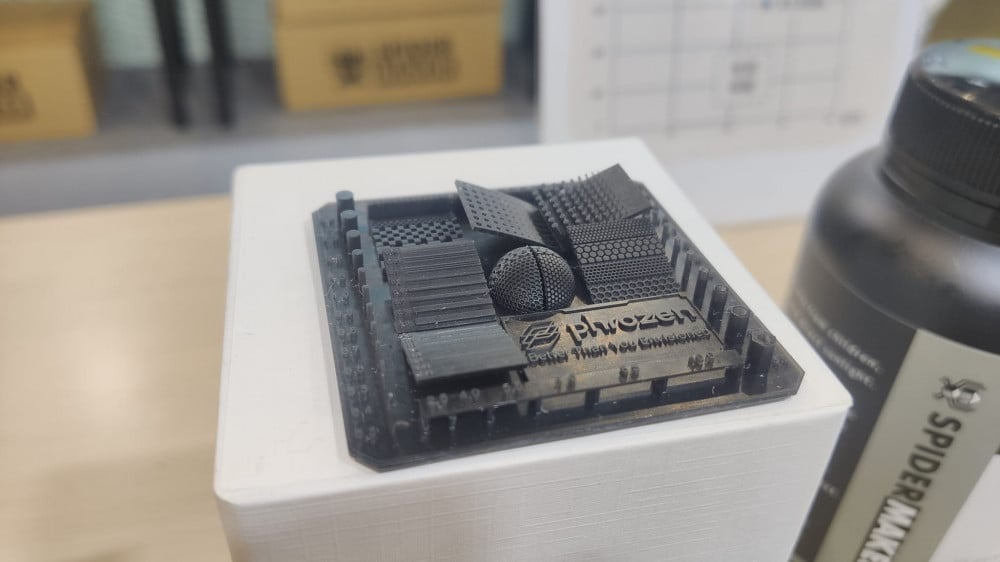

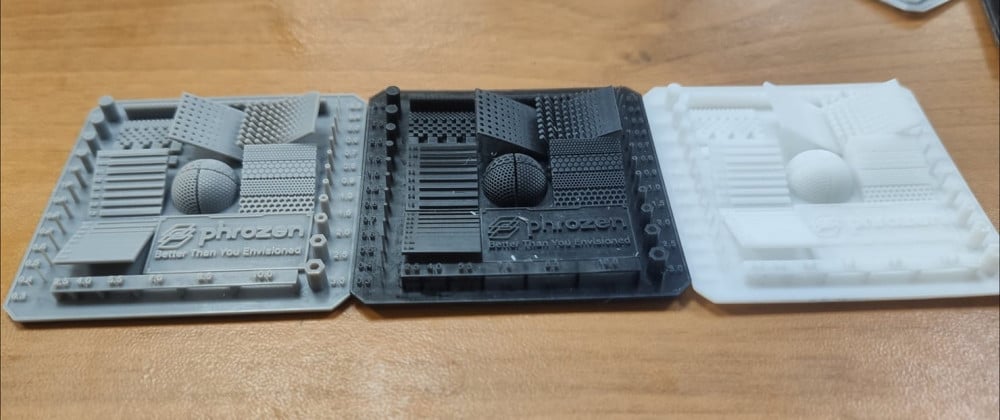

✅ Wide Compatibility: Works seamlessly with most LCD 3D printers, including brands like Anycubic, Elegoo, Phrozen, and more.

✅ Consistent Performance: Known for its stable viscosity, low shrinkage, and reliable curing properties, ensuring consistent results across prints.

Technical Specifications:

| Viscosity: | 90-110 cps |

| Liquid Density: | 1.11 g/cm³ |

| Surface Hardness: | 82D |

| Tensile Modulus: | 1489 MPa |

| Tensile Strength: | 36.6 MPa |

| Fracture Elongation: | 8.6% |

Final Thoughts:

SpiderMaker EX-300BL Engineering All-Rounder Resin (Black) is more than just a resin—it’s a robust material designed to meet the demands of modern engineering and prototyping. With its exceptional mechanical properties, sleek black finish, and versatility, it is the ultimate choice for engineers, designers, and hobbyists alike. Elevate your 3D printing capabilities today with this premium engineering-grade resin!

📰Comparison table between Resin brands

❗How to calibrate any resin on a LCD printer

Printing Parameters