Product Information: Jamghe Pro Model Resin (Almond) for LCD / DLP 3D Printers, 500g

🔸 Brand : Jamghe

🔸 Material : Photopolymer Resin (Specially Formulated for High-Precision Dental Models with Excellent Durability and Surface Finish)

🔸 Color : Almond

🔸 Net Weight : 500g

Why Choose Jamghe Pro Model Resin (Almond)?

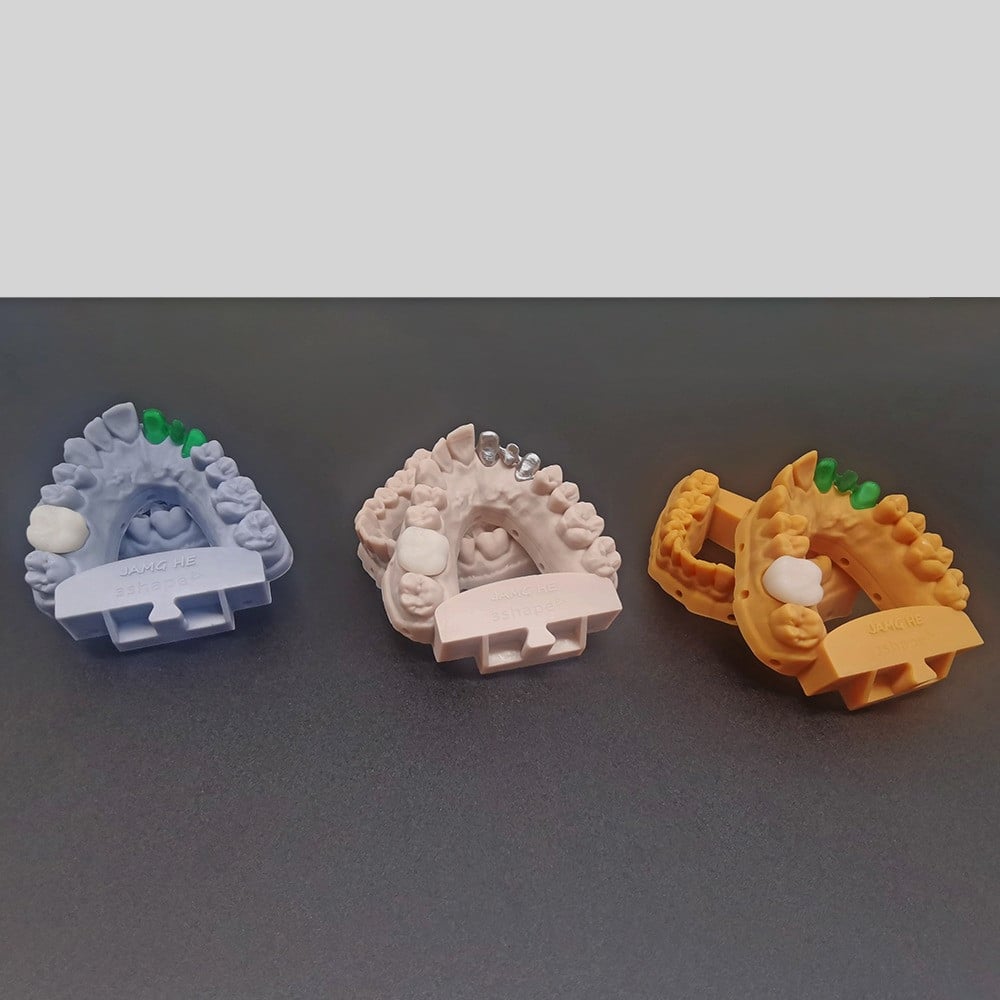

Jamghe Pro Model Resin (Almond) is a premium photopolymer resin designed specifically for dental professionals using LCD/DLP 3D printers. It is optimized to produce highly accurate and durable dental models with an almond color that mimics the natural appearance of teeth and gums. This makes it ideal for creating precise orthodontic models, study models, surgical guides, and custom dental appliances. Its smooth surface finish and excellent dimensional stability ensure consistent results for professional dental practices.

What Makes It Special?

🔹 High Precision : Designed for ultra-detailed prints, capturing every detail required for dental applications.

🔹 Natural Almond Color : Mimics the natural appearance of teeth and gums, making it ideal for realistic dental models.

🔹 Smooth Surface Finish : Produces clean, glossy surfaces with minimal post-processing required.

🔹 Durability : Offers excellent strength and resistance to wear, ensuring long-lasting functional models.

🔹 Wide Compatibility : Works seamlessly with most LCD/DLP 3D printers, including popular brands like Anycubic, Elegoo, Phrozen, and others.

Technical Specifications:

| Surface Hardness (Shore D) | 85-90 |

| Body Contraction (%) | 4%-6% |

| Tensile Strength (MPa) | 40-50 |

| Elongation at Break (%) | 8-12% |

| Bending Strength (MPa) | 35-45 |

| Bending Modulus (MPa) | 800-1000 |

Recommended Printing Parameters:

🖨️ Printer Compatibility : LCD/DLP 3D printers

⏱️ Bottom Exposure Time :

- Standard LCD/DLP Machine: 20-80 seconds

- 🔢 Ground Floor Number : 4-6 layers

⏱️ Normal Exposure Time :

- Standard LCD/DLP Machine: 4-15 seconds

- ↕️ Lifting Distance : 5-8 mm

- ⬆️ Lifting Speed : 50-100 mm/min

Applications of Jamghe Pro Model Resin (Almond):

🦷 Orthodontic Models : Create precise dental models for aligner fabrication, retainers, and other orthodontic appliances.

🎯 Study Models : Produce detailed study models for diagnostic and treatment planning purposes.

🛠️ Surgical Guides : Design accurate surgical guides for dental implant procedures.

🎨 Custom Dental Appliances : Craft custom dental appliances such as crowns, bridges, and veneers.

Why Customers Love It:

✅ Ultra-High Precision : Captures fine details, making it perfect for intricate dental models.

✅ Natural Almond Color : Provides a realistic appearance that closely mimics teeth and gums, enhancing visualization.

✅ Smooth Surface Quality : Produces glossy, smooth surfaces with minimal post-processing.

✅ Durability : Offers excellent strength and resistance to wear, making it suitable for functional dental models.

✅ Wide Compatibility : Works seamlessly with most LCD/DLP 3D printers, ensuring consistent results across different devices.

✅ Reliable Results : Known for its stable viscosity, low shrinkage, and reliable curing properties, ensuring high-quality prints every time.

Final Thoughts:

Jamghe Pro Model Resin (Almond) is a premium material designed specifically for dental professionals who demand precision, durability, and realism in their 3D prints. Whether you're creating orthodontic models, study models, surgical guides, or custom dental appliances, this resin delivers exceptional results with its smooth surfaces, sharp details, and natural almond color. Elevate your dental practice today with this high-performance resin!

📰Comparison table between Resin brands

❗How to calibrate any resin on a LCD printer

Product advantage:

Supper low shrinkage rate 0.95%-1.15%

Low odor and no toxic and anti-scratch

Non deformation within 5 days

Perfect for restoration and implant model

Color option: yellow, skin, orange yellow

Non VOC, RoHS Reach EN71-3certificated

Compatible for most 3D printer

Technical specification:

Flexural modulus:1162.23Mpa ±10%

Elongation at break:12.89% ±10%

Flexural strength :52.48MPa ±10%

Hardness(Shore D):85-88 D

Density:1.05—1.28 g/cm3

Notched impact strength: 144 j/m ±10%

maximum pulling strength: 2473N ±10%

Viscosity:150-300MPa·s

Tensile strength:52.7 MPa ±10%

Tensile modulus:397.96Mpa ±10%

℃Testing room temperature:23℃±2

Testing room humidity :50%RH±5%RH

Testing standard of test strip: ASTM

Post curing: test strip in water for 2 mins post curing with 200mw/cm²405nm.

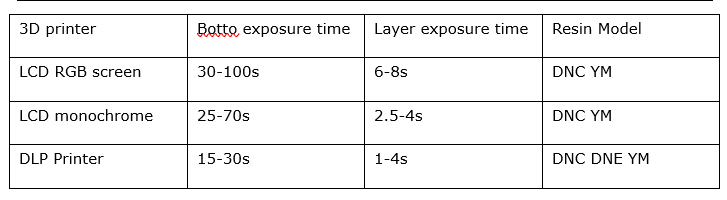

Printing parameter

Only has to adjust the exposure times the layer height, and leave the rest as it was.

Cleaning and post-curing

Step1, Spray with Isopropanol, then blow resin away with cool wind.

Step2, Prepare two containers with Isopropanol (alcohol> 95%), and place the jobs into the first container and slightly shake it, then soak in the second container for about 1 minute (dental resin should not exceed 30 seconds).

Step3, Flush with water before dry it, do make it sure it ‘s 100% dried as residuary alcohol may cause white spot or crack on jobs.

NOTE: 1. Do not use ultrasonic for cleaning, especially for casting resin.

2. Dental resin jobs are recommended to be cleaned before takeoff from the platform to avoid deformation.

Post-curing:

1. The curing time is proportional to the volume of the work piece and inversely proportional to the optical power of the curing chamber. Example: 100 watt LED curing box, jewelry jobs is recommended to be cured with soaking in water for 20-30 minutes.

2. The post-cure time of dental casting resin, dental non-casting resin and jewelry mold resin shall not more than 5 minutes.

3. Work-pieces should be in the water during post-curing to prevent deformation especially for dental and jewelry.

4. Don’t forget to use cool air to dry it after post-curing.

Warning:

1. This material should not be in contact with eyes, skin or clothing, and should not be tasted or eaten.

2. If you accidentally touch your eyes or skin, immediately rinse with water for about 20 minutes and seek medical advice if necessary.

3. Please pay attention to air circulation and take protective measures when using. Wash thoroughly after handling.

4. The product is in a liquid state with a slight odor. Wear a mask and gloves.

5. The product should be stored in a sealed container. After use, it should be filtered and keep back in bottle on time and placed in a dry and well ventilated place. It should not be exposed to sunlight.

6. Shake well before use, and leave it for 30 minutes to eliminate air bubbles that generated during the shaking process.

7. The ambient temperature is recommended to be controlled at 25-30 degrees Celsius, and during the printing should avoid any lights.

8. Dispose of waste in accordance with local environmental regulations.

9. Storage environment: Store in cool and dry place, and avoid sunlight, recommended temperature at 25-30 degrees Celsius.